Product Comparison

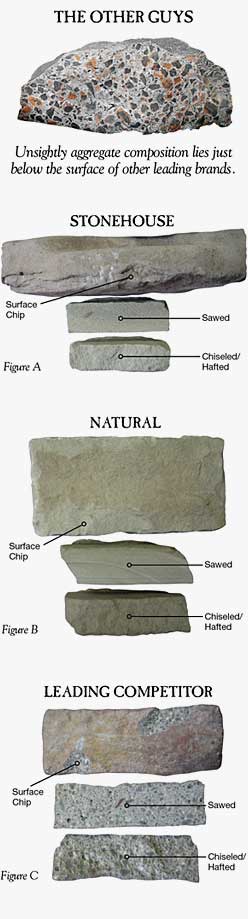

Stonehouse Solutions Remanufactured StoneT process produces a more natural like stone product than other stone manufacturers. To the right we have demonstrated a comparison in Stonehouse Solutions stone (Figure A), Natural stone (Figure B), and a leading competitor (Figure C). The top piece in each example shows a stone with a surface chip. The middle example is a sawn piece, which is commonly necessary for completing a project. The bottom piece is a broken or chiseled piece which clearly with our competitor’s product would be nearly impossible to disguise the aggregate in application. Note the similarity in our products to natural, and the unsightly aggregate in the competitor.

MANUFACTURED STONE

Most manufactured stone companies use large unsightly aggregates in composing their stone products. This makes it difficult to disguise cuts in the stone during the installation process. It is almost always necessary to cut or chisel some stones in any project, this gravel like aggregate does not reflect a natural stone appearance. As you can see from the photos at the top right of this page, the appearance of the aggregate is just behind the surface of the stone. Additionally most manufactured stone companies do not color their products throughout, which could lead to fading in color over time. Some do color their products but continue to use large aggregate making no improvement to the appearance of the inside of their products. Stonehouse Solutions remedy these imperfections in manufactured stone with our Remanufactured StoneTM process. We manufacture our products from crushed stone and color them throughout, recreating new stone, from stone. Our products stand up to the same rigorous testing as do theirs, with no change in Compressive Strength, and in some cases dramatically outperforming, resulting in a more natural stone appearance through and through.

NATURAL STONE

Natural stone while beautiful can be more costly (from 50-60% more depending on area) in comparison to manufactured stone products. It is anywhere from 6 to 8 inches thick, which requires footers, ledgers, and wall ties in order to support the weight of the stone. Thin Veneer is being used in many more diverse applications, in part, because it is so versatile. It may be used in situations where a full bed stone cannot. It does not require a ledger, footers, or wall ties like natural stone. Natural stone also requires superbly skilled masons to chisel and work the stone then lift into place, which translates into more expensive labor costs. Besides saving time in completion, you will save money on materials and labor by selecting thin veneer instead of natural. Additionally, specific colors and textures are sometimes unavailable in Natural Stone. Stonehouse products are available in many diverse colors and styles. Quarries do not always uncover what is in demand, and when they do it can be extremely costly. All of our styles can be manufactured in any of our colors with no variation in price based on style or color selection. Because our stone is most like natural stone in its make up, you may create the same long lasting natural stone appearance with a much more affordable Remanufactured StoneTM product.